There is an explosion of new shoe creations made possible by the advent of additive manufacturing and advanced materials. These enable the creation of footwear designs inconceivable using traditional means. While many of the designs have strong esthetic attributes, there are also new ergonomic opportunities not availed within traditional design methods.

Listed below are a few design considerations from the perspective of the ergonomics of movement:

CONSIDERATIONS:

- The heel should be lower than the area behind the big toe. Moving with the body mass forward in the gait cycle offers a dramatically more engaged neuromotor capacity. By elevating the sole under the ball of the foot, the forefoot is facilitated to make first contact with the ground. In normal shoes with an elevated heel, the opposite occurs where we encounter a strong heel strike, high shock loads, and reflex inhibition. By elevating the area under the ball of the foot, specifically the 1st, 2nd, and 3rd toes, body mass is encouraged to shift forward towards a dramatically more dynamic movement engagement.

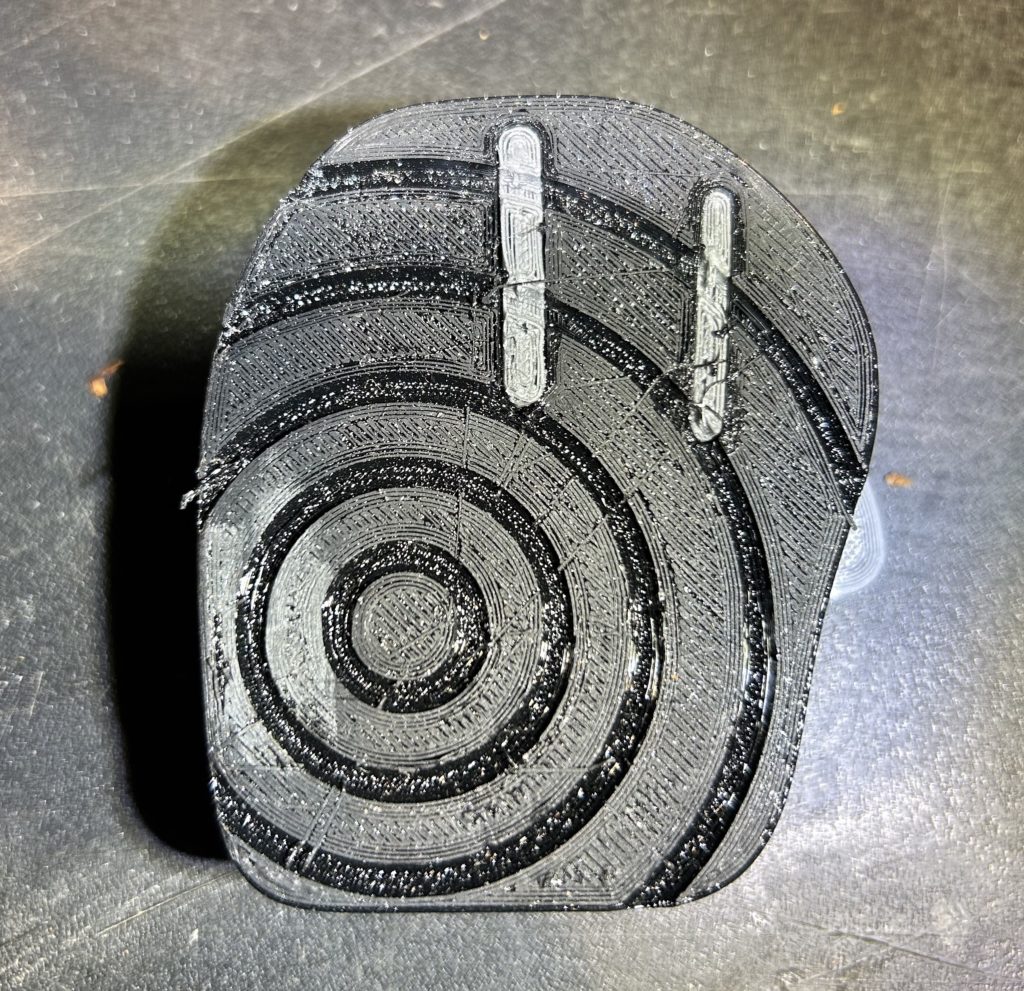

This is discussed in this post: OUTSOLE - The arc of the radius of the sole of the shoe is greater than the arc of the sole in forefoot gait. This results in the length of the shoe commonly being too short to engage the ball of the foot in gait without jamming the big toe into the toe box. A design that allows for ~7% additional length yet maintains a firm fit on the foot would be optimal. This is quite challenging to attempt in traditional shoe design. Note how this is handled in the additive-manufactured shoe pictured above.

- The squishiness of the sole inhibits the activation of gait automaticities. The sole should be firm enough so that the gait reflexes are enabled but not so firm that the gait reflex potential is exceeded. This can be individually evaluated by assessing the rate of change in acceleration in the vertical axis while wearing prototype footwear. The design of the shock absorption of the sole should be configurable (infill setting?) so that the dominant frequencies of the rate of change in acceleration(Jerk) taper off above 5 Hz.

This is discussed in the post: A COMPREHENSIVE DESCRIPTION OF GAIT

This design attribute can facilitate the development of gait mechanics in the body so this metric should be revisited and the shoes reprinted regularly to remain maximally supportive. The goal is to develop body shock absorptive mechanisms to the point where no shock insulation is applied – a pure Paleo Footwear design.

- Tread Design is often conceptualized on a linear ground contact in the vector of movement. In other words, the shoe tread is usually laid out in a grid perpendicular to the length of the shoe. When more dynamic movement forms are engaged, this tread configuration inhibits rotation of the foot/shoe complex. By designing a circular tread pattern as shown in the picture at right, with the circle center positioned under the 1st. Metatarsal/1st. Phalanges joint, the foot can more easily rotate about this axis within the shoe, extending the scope of action while reducing structural strain.

- The width of the sole of the shoe:

on the lateral(outside) edge should be wide enough so that the foot does not roll off of the edge when the foot pushes the body sideways (as much as a 45° downward angle).

on the medial(inside) edge should not overhang at all so that the foot can cut into the ground to push the body sideways. - The sole of the shoe at the toe box should be square to the vector of motion and filleted(rounded over) when viewed from the side – the sole makes an arc contacting the ground, to not interfere with FOREFOOT GAIT.